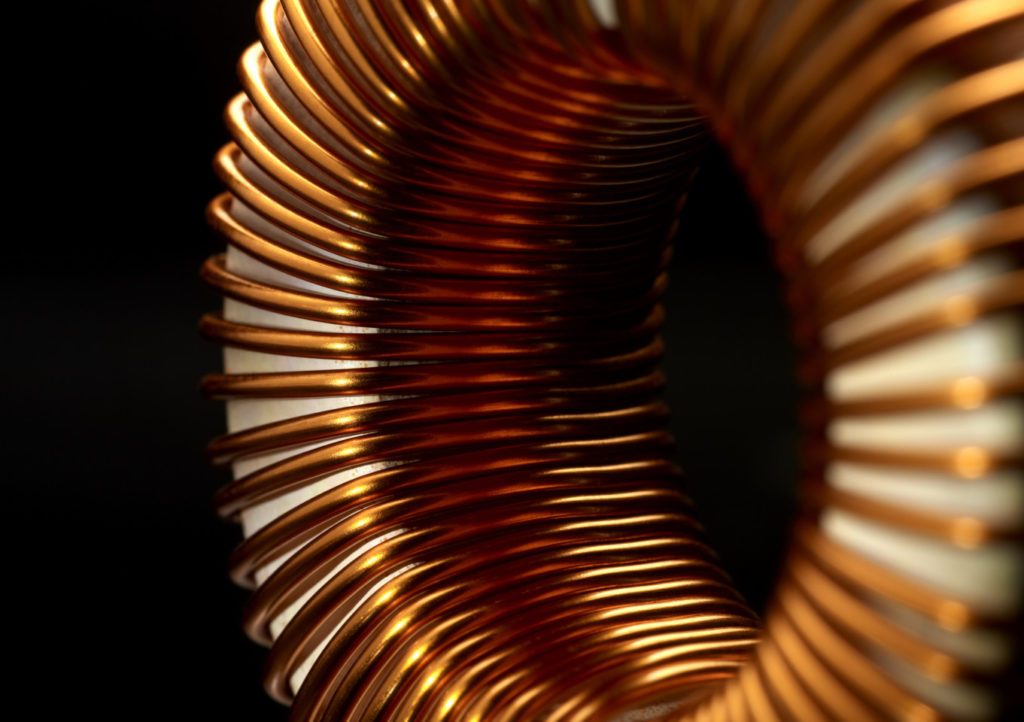

Available in wire

Available Conductive Copper Grades

What are the benefits of using Conductive Copper?

Copper Alloys offer many manufacturing benefits including strength, conductivity, corrosion resistance, machinability and ductility. With superior electrical and thermal conductivity, and an attractive appearance, Copper Alloys are suitable for a wide range of applications.

Conductive Copper wire is an excellent solution for creating a more conductive or efficient connection between two points. It has the highest conductivity of any non-precious metal and is ideal for use in electrical applications due to its durability and high performance. Conductive copper wire is also known as "fine silver" or even "white gold" because of its silver appearance. The most common form of copper is high conductivity copper, which is widely available in high quality.

The most common form of copper is high conductivity copper, which is widely available in high quality. This grade of copper is Electrolytic Tough Pitch (Cu-ETP), which has a 100% IACS.

For specific applications, oxygen free copper (Cu-OF) is available which prevents embrittlement and material cracking. Additionally, if increased strength is required, alloying elements such as tin, magnesium, chromium and iron can be added in small quantities. These alloys increase the strength but reduce conductivity.

As part of the Knight Group Precision Metals EU are specialist manufacturers of Wire and Cable and can provide free quotations on your requirements. Please get in touch to arrange this.

High Conductivity Copper (Cu-ETP) & Oxygen Free Copper (Cu-OF)

High Conductivity Copper (Cu-ETP)

Electrolytic Tough Pitch high conductivity copper is the standard grade of copper for electrical conductivity applications, with 100% IACS. A higher grade Cu-ETP1 is made from Grade A copper cathode.

Oxygen Free Copper (Cu-OF)

For special welding and brazing applications, an oxygen free copper is available with 102% IACS. This copper avoids embrittlement in a heated reducing environment as hydrogen reacts with the oxide in the metal to form steam and material cracking.

| CONDUCTIVE COPPER ALLOYS GRADE DESIGNATIONS & CHEMICAL COMPOSITIONS (% BY WEIGHT) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MATERIAL DESIGNATION EN1652 or Alloy | NEAREST FIT | TYPICAL CHEMICAL COMPOSITION % | |||||||||||||

| Symbol/ Name | Number | UNS | BS 2870 | Cu | Be | Co | Fe | Mn | Ni | P | Pb | Sn | Zn | Others | Impurities |

| HIGH CONDUCTIVITY COPPERS | |||||||||||||||

| Cu-ETP | CW004A | C11000 | C101 | 99.9 min | - | - | - | - | - | - | 0.005 | - | - | Bi: 0.0005 O: 0.04 | - |

| Cu-ETP1 | CW003A | C11040 | - | Available by Request | |||||||||||

| Cu-OF | CW008A | C10200 | C103 | 99.95 min | - | - | - | - | - | - | 0.005 | - | - | Bi: 0.0005 | 0.03 |

| MECHANICAL PROPERTIES FOR COPPER SPECIFICALLY USED IN ELECTRICAL CONDUCTOR APPLICATIONS | ||||||||

|---|---|---|---|---|---|---|---|---|

| Material Designation BS EN 13602:2013 | Nearest equivalent | Material Condition | UTS Nominal Rm N/mm² | % Elongation 200mm | Conductivity | |||

| Symbol | Number | UNS | BS 4109 | Single Wire | Multi Line | % IACS | ||

| Cu-ETP | CW004A | C10100 | C101 | Annealed | 200 | 10 to 33 | 8 to 26 | 100 |

| Cu-OF | CW008A | C10300 | C103 | |||||

| Cu-ETP* | CW004A | C10100 | C101 | Annealed | 200 | 5 to 31 | 5 to 22 | 92.6 to 99.0 |

| Cu-OF* | CW008A | C10300 | C103 | |||||

| Cu-ETP | CW004A | C10100 | C101 | Hard Drawn | 360 to 460 | - | - | 93.4 to 97.1 |

| Cu-OF | CW008A | C10300 | C103 | |||||

| Cu-ETP* | CW004A | C10100 | C101 | Hard Drawn | 360 to 460 | - | - | - to 96.2 |

| Cu-OF* | CW008A | C10300 | C103 | |||||

| Cu-ETP1 | CW003A | C11040 | - | Available by Request | ||||

| CONDUCTIVE COPPER ALLOY FEATURES AND APPLICATIONS | ||||||

|---|---|---|---|---|---|---|

| MATERIAL DESIGNATION EN1652 or Alloy | NEAREST FIT | Key Features | Key Markets | Applications | ||

| Symbol/ Name | Number | UNS | BS 2870 | |||

| HIGH CONDUCTIVITY COPPERS | ||||||

| Cu-ETP | CW004A | C11000 | C101 | Cu-ETP has no susceptibility to hydrogen embrittlement as well as a high electrical conductivity of 101% IACS. This is due to a high purity and an absence of deoxidisers. | Architectural, Chemical Engineering, Culinary, Electrical | Electrical Components, Chemical Process Equipment, Radiators, Kitchen Appliances, Conductors, Transformer Windings, Wire: Shapes, Knitting, Braiding, Weaving |

| Cu-ETP1 | CW003A | C11040 | - | Available by Request | ||

| Cu-HCP | CW021A | C10300 | C102 | Cu-HCP is a de-oxidised,oxygen-free Copper with a low residual phosphorus content. Offers excellent formability and weldability, as well as good soldering and brazability. | Electrical, General Manufacturing | Electrical Contacts & cable Industry, Pressure Vessels |

| Cu-OF | CW008A | C10200 | C103 | Cu-OF is a High purity Copper Oxygen Free (maximum of 10ppm) alloy, offering 100% IACS. It is immune from hydrogen embrittlement and offers similar formability to Cu-ETP. | Electronics, Telecommunications | Printed Circuits, Electronic Components, Telecommunication Cables |

Stripe Processing

All data is provided for informational purposes only. In no event will Precision Metals EU and its partners, be liable with respect to any action taken by any third party arising from using the information taken from our online or printed sources. Chemical and Mechanical Properties should not be construed as maximum or minimum values for specifications, nor should the information be used to assess suitability for a particular use or application. The information and data provided are deemed to be accurate to the best of our knowledge and may be revised anytime without notice, and assume no duty to update.